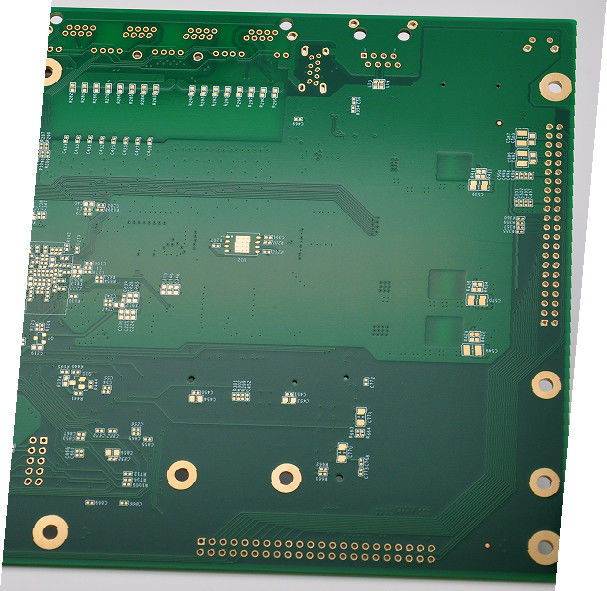

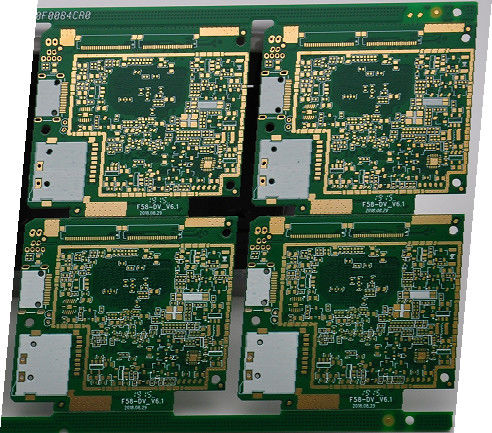

Rigid Blank heavy Copper PCB Board Power convert PCB Board DC AC Device Applied

Key Specifications/Special Features:

Layer : 4 Layers

Base Material : FR4

Copper Thickness : 2 / 2 / 2 / 2oz,

Board Thickness : 1.60 mm

Min. Hole Size : 6 mil / 0.15 mm

Min. Line Width : 4 / 4 mil

Min. Line Spacing : 4 / 4 mil

Surface Finishing : Immersion Tin

Fire-proof level : 94v0

Certificate : UL, CQC, TS16949, ISO14000, ROHS

Rigid PCB Technical Capability:

| Items |

Technical Capability |

| Layers |

1-28 layers |

Min. line width/space |

4mil |

|

Max.board size (single&doule

sided)

|

600*1200mm |

Min.annular ring width: vias |

3mil |

| Surface finish |

HAL lead free,gold flash

Immersion silver,Immersion gold ,Immersion Sn,

hard gold,OSP,ect

|

Min.board thickness(multilayer) |

4layers:0.4mm;

6layers:0.6mm;

8layers:1.0mm;

10layers:1.20mm

|

| Board materials |

FR-4; high Tg; high CTI; halogen free; high frequency(rogers,taconic,

PTFE,nelcon,

ISOLA,polyclad 370 HR); heavy copper,

Metal base clade laminate

|

Plating thickness (Technique:

Immersion Ni/Au)

|

Plating type: Imm Ni, Min./Max thickness:100/150U'' Plating type: Imm Au, Min./Max thickness:2/4U'' |

| Impedance control |

± 10% |

Distance between

line to board edge

|

Outline: 0.2mm

V-CUT: 0.4mm

|

|

Base copper thickness(Inner

and outer layer)

|

Min. thickness: 0.5 OZ Max.thickness: 6OZ |

Min.hole size(board thickness ≥2mm) |

Aspect ratio≤16 |

| Finished copper thickness |

Outer layers:

Min.thickness 1 OZ,

Max.thickness 10 OZ

Inner layers:

Min.thickness :0.5OZ,

Max.thickness : 6 OZ

|

Max.board thickness(single&doule sided) |

3.20mm |

Quality Goal:

| Category |

Performance indicator |

Quality Goal |

|

Delivery

|

Customer service rate |

99.9% |

| Semi Finished product |

Process inspection pass rate |

100% |

| Finished product |

FQA Rebate rate |

0.1% |

| Scrapped |

1L scrap rate |

0.5% |

| 2L scrap rate |

1% |

| Multi Layer scrap rate |

2% |

| Customers |

Customer complaint rate |

0.8% |

| Customer return rate |

0.5% |

| Customer satisfaction |

99% |

Quality assurance :

Every production process has a special person to test to ensure quality, AOI, E-testing, Flying Probe Test.

Have professional engineers to check the quality

All products have passed CE, FCC, ROHS and other certifications

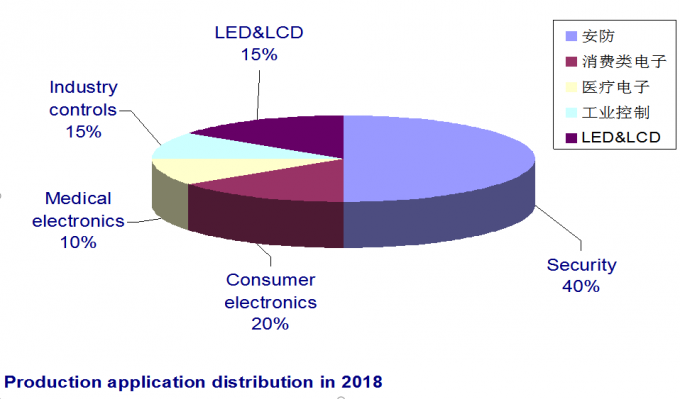

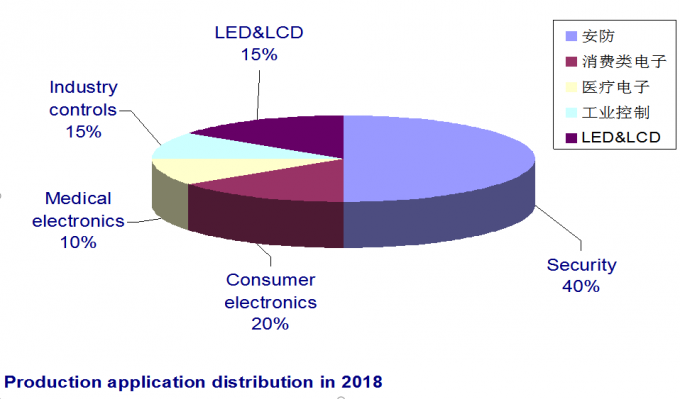

Product Application Field :

FAQ:

1. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

2. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

3. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

4. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

5. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

6. What are the main factors which will affect the price of PCB?

Material;

Surface finish;

Board thickness, Copper thickness;

Technology difficulty;

Different quality criteria;

PCB characteristics;

Payment terms;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!